Pixact在线颗粒分析技术在制浆造纸行业中的应用

点击下载

Pixact在线颗粒分析技术在制浆造纸行业中的应用

Pixact measurement technology can be utilized in several production phases and process operations of The Pulp & Paper industry

Pixact公司的在线颗粒分析技术可应用于制浆造纸行业的多个生产工段。如:可用于实时监测悬浮液中的纤维、颗粒物、杂质和沉淀等固体颗粒物的形态及粒径分布;可用于实时监测纸浆去木质化过程的气体分散情况;可用于提高纤维纸浆的产率、增进去木质化的过程、降低能量消耗、减少化学物质排放;可应用到从初期的纸浆工艺优化直至末期的废水处理监测。来自芬兰坦佩雷的Pixact公司,核心技术和团队成员都来自于TUT芬兰坦佩雷理工大学,在颗粒成像技术及算法方面世界领先,制造出性能卓越的、模块化的、定制化的在线颗粒分析系列产品。以下,我们将介绍Pixact公司的四种产品在制浆造纸行业中的应用。

The Pulp & Paper industry can utilize Pixact measurement technology in several production phases and process operations. The Pixact online measurement systems for solid particles(including fibers, fines, impurities and precipitates)and gas content estimate enable the replacement of laboratory analyses with online quality monitoring and process control to optimize, e.g., energy consumption and chemical dosage. Pixact applications range from the early stages of pulp production to the water treatment facilities in the paper mill. In the following, four Pixact products and their applications in the pulp and paper industry are presented.

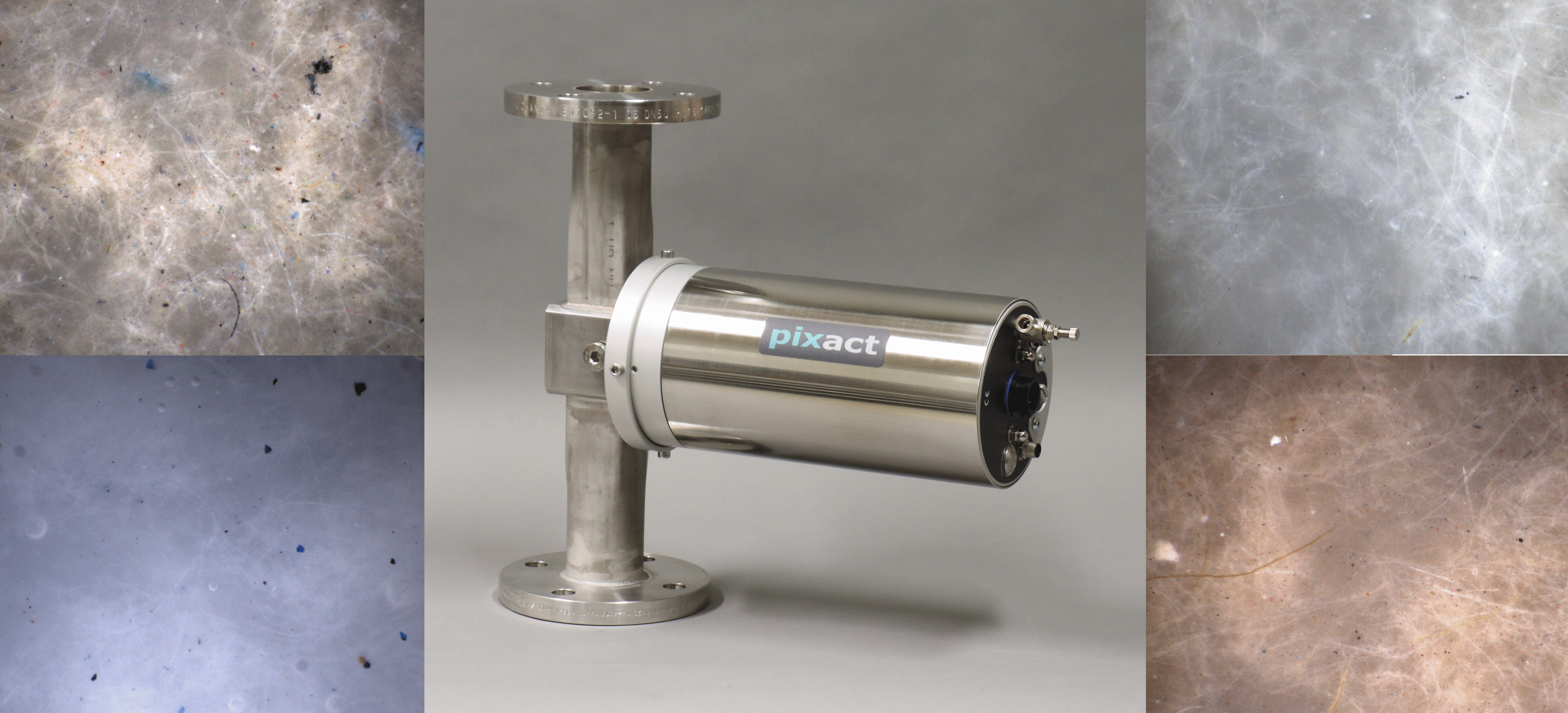

PSM浆料监测系统可用于实时监测悬浮液中的残留颗粒物(杂质、浆块、纤维、塑料固形物等)、颜色和光泽度等,有助于我们实时监测纸浆悬浮液的尘埃度,并将尘埃度控制在规格范围内。该系统可直接安装在管线上,全自动获取数据,及时可靠,再也不需要耗费人工和时间来完成频繁样品采集和送检。

The Pixact Stock Monitoring PSM is designed for the analysis of impurities and color of flowing pulp suspension. The PSM system is installed directly on the process line. The system provides real-time measurement data without the need for preparing samples for analysis.

PPM颗粒监测系统可用于实时监测浆料中的纤维特性,针对传统纤维和微纤化纤维皆可获取其尺寸和形态数据。如:纤维长度、纤维细度、原纤化指数F.I.、纤维形态(转曲、卷曲、其他形态)等。该系统可选配自动稀释装置,可适应各种浓度的浆料的全自动监测。

Pixact Particle Monitoring PPM technology can be used for the analysis of fiber characteristic in pulp and paper applications. Optimized analysis algorithms are developed for both traditional fiber and micro-fibrillated fibers. In online applications the PPM system is equipped with an automatic dilution station. The system produces real-time data on fiber size and morphology, such as: Fiber length and width, Fibrillation index, Fiber morphology(kinks and curls)and others.

PPM颗粒监测系统也可用于纸浆造纸生产中的各种过滤和水处理过程中,用于监测滤液和废水中的

微粒、细粒、纤维和絮聚物等各类颗粒物的图像及粒度分布等。该系统可以选配自动稀释装置,可以安装在抄纸工段的白水循环设备上,用于对颗粒物进行实时分析,可为我们带来非常大的经济效益。

The Pixact Particle Monitoring technology can be applied various filtrates and water treatment processes in pulp and paper production to produce in-depth measurement data on particle populations far beyond the capabilities of the traditional turbidity measurement. For example, in white-water analysis, the measurement system is equipped with a dilution unit and installed on the paper machine white-water circulation to analyse particle populations. The PPM classifies detected particles into categories, such as: Micro-particles, fines, fibers and flocs.

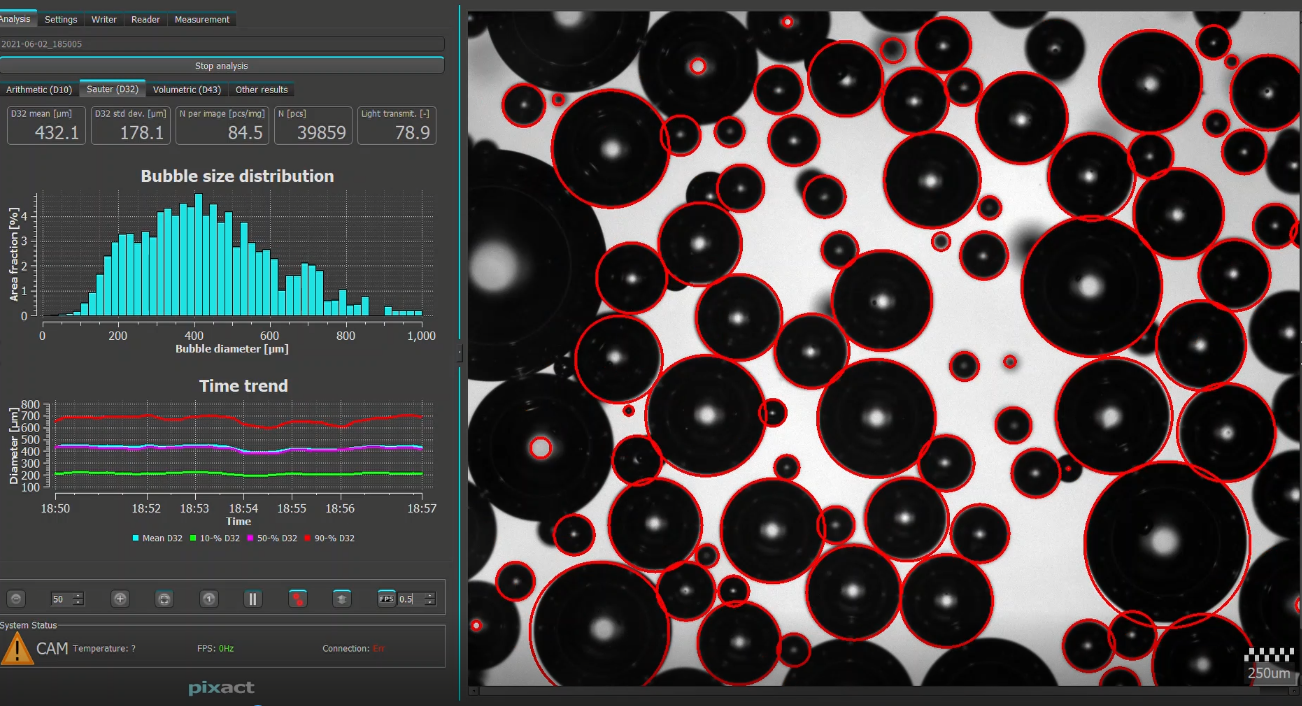

PBM气泡监测系统是为工业过程中在线分析气泡悬浮液和泡沫体系而专门设计,可以得到:气泡尺寸分布、平均气泡分布、标准偏差、索特平均直径和累积分布等。PBM技术可以被用于高空气含量的泡沫和低空气含量的气泡悬浮液。PBM气泡监测系统在纸浆造纸行业可用于浆料制备中的空气检测、去木质化过程的气体分散状态监测、纸浆浮选效果评估、泡沫成型和模塑成型中的泡沫质量分析等。

Pixact Bubble Monitoring technology is designed for the online analysis of bubble suspensions. The measurement system is applicable to any type of gas dispersion: It can be used from the detection of individual gas bubbles in liquid to the analysis of high gas content foams. Application in the Pulp & Paper industry include: detection of air in stock preparation, analysis of oxygen dispersion in delignification, analysis of the performance of flotation, analysis of foam quality in foam-laid forming and molded pulp.

PCM结晶监测系统专为在线结晶工艺过程而设计,新颖的基于光学成像的过程监测探头是全球在线结晶成像技术及算法的领导者,通过直接光学成像技术进行实时图像观测,获取图像后用专利的算法进行图像分析,以监测晶体尺寸、尺寸分布、生长速率和颜色等。Pixact的使命是为实验室研发和工业过程提供创新型工具,用于提高过程控制和产品的质量稳定性。

The Pixact Crystallization Monitoring PCM technology is designed for the online measurement of crystallization processes. The technology combines in-situ process microscopy with advanced image analysis techniques. PCM provides a live camera view of the process and detailed real-time measurement data on crystal characteristics, such as size distribution, morphology and concentration. The measurement results produced by PCM help you to optimize, control and troubleshoot your process efficiently. With PCM you can increase the yield and capacity of your process and minimize quality variations in the final product.

PCM结晶监测系统基于模块化理念进行研发和设计制造,可以安装在反应釜、反应罐体、结晶器、过程管线等,可以被用于连续生产过程或批次生产过程。在纸浆造纸行业,PCM结晶监测系统可用于实时监测结晶过程的晶体成核、晶体形态、晶体数量和粒度分布,可用于优化蒸发结晶工艺,显著提高能源效率。

Equipped with flexible installation mechanics, PCM can be fitted into a variety of applications from laboratories to manufacturing-scales. The technology is utilized in both continuous and batch crystallization processes. Pixact Crystallization Monitoring technology can also be used to optimize its evaporation crystallization process and energy efficiency significantly in paper and pulp industry.

德国知名的造纸和制浆工业杂志也刊登过Pixact在线颗粒分析技术在制浆造纸行业中的应用:http://www.fibers-in-process.de/epaper/fip/272/epaper/3690/44/index.html。

German professional magazine for paper and pulp industry has published an article about Pixact online measurements. You can read the article in http://www.fibers-in-process.de/epaper/fip/272/epaper/3690/44/index.html.